Please note that the site is under development! Technical support: info@sidera.energy

FUEL SYSTEM

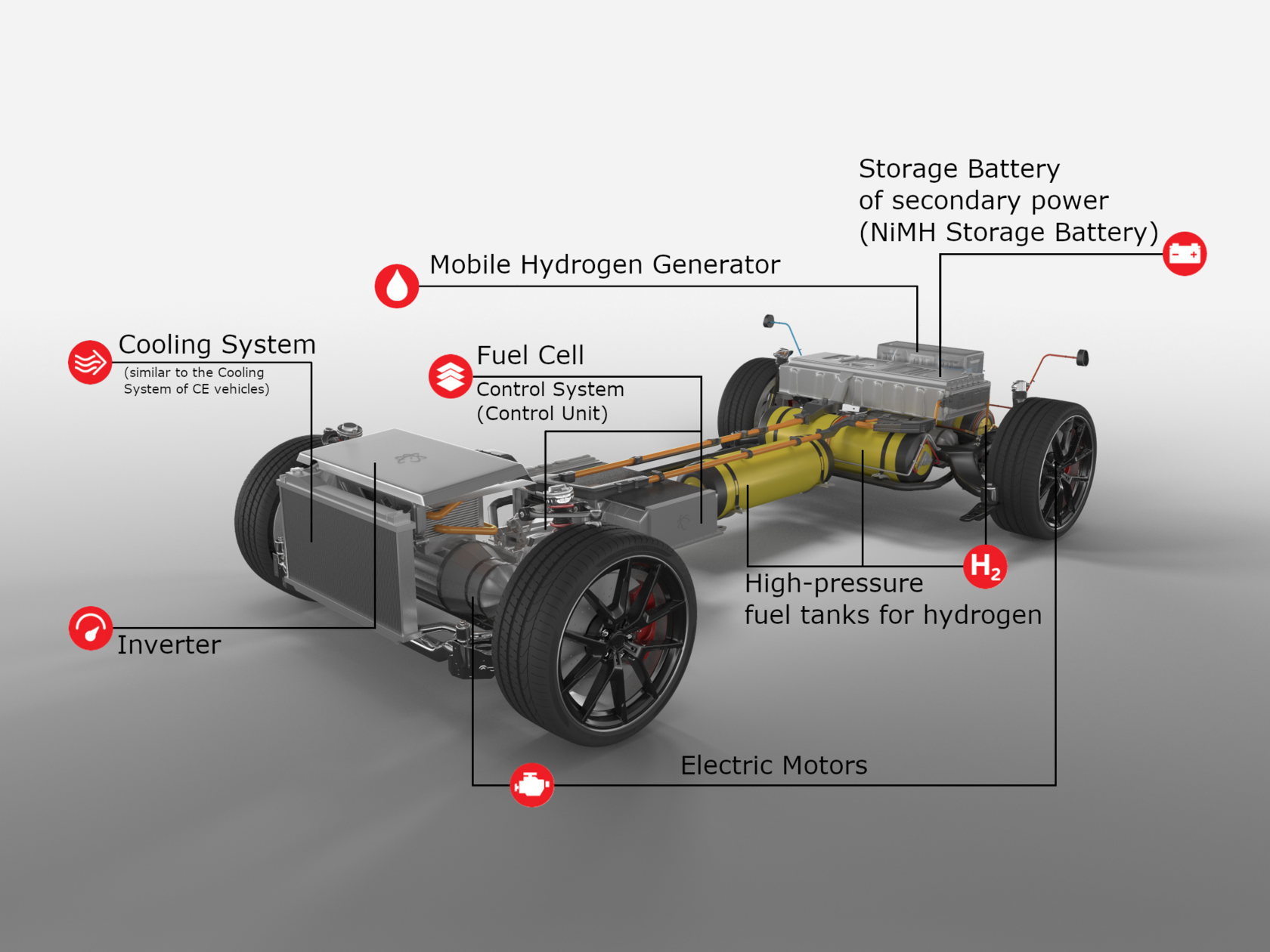

of the hydrogen-powered car on the example of SIDERA APUS

Unlike classic electric vehicles that use electric energy stored in a battery, hydrogen fuel cell electric vehicles generate their own clean energy through a chemical reaction between hydrogen and oxygen in a fuel cell battery.

Following the principles of import substitution, our team has been designing components for several years to create an innovative power plant for hydrogen transport.

Following the principles of import substitution, our team has been designing components for several years to create an innovative power plant for hydrogen transport.

THE MAIN COMPONENTS OF THE DEVELOPED POWER PLANT:

— Fuel cell battery;

— Buffer power battery (secondary power source);

— Hydrogen composite tank with gas supply system;

— Management and control system;

— Power Converter;

— Air supply system;

— Cooling system.

— Buffer power battery (secondary power source);

— Hydrogen composite tank with gas supply system;

— Management and control system;

— Power Converter;

— Air supply system;

— Cooling system.

Diagram of the SIDERA APUS hydrogen electric vehicle

The "heart" of the power plant is an electrochemical generator SEGH2, in which a chemical reaction occurs between hydrogen from fuel tanks and oxygen from the surrounding air.

During the reaction, all the systems of the car including traction motors are provided with electricity. The only emission is WATER.

Importantly, the excess heat generated by the fuel cell can be used to warm up the interior of the car in the cold season, which significantly improves it's performance in comparison with battery electric vehicles.

During the reaction, all the systems of the car including traction motors are provided with electricity. The only emission is WATER.

Importantly, the excess heat generated by the fuel cell can be used to warm up the interior of the car in the cold season, which significantly improves it's performance in comparison with battery electric vehicles.

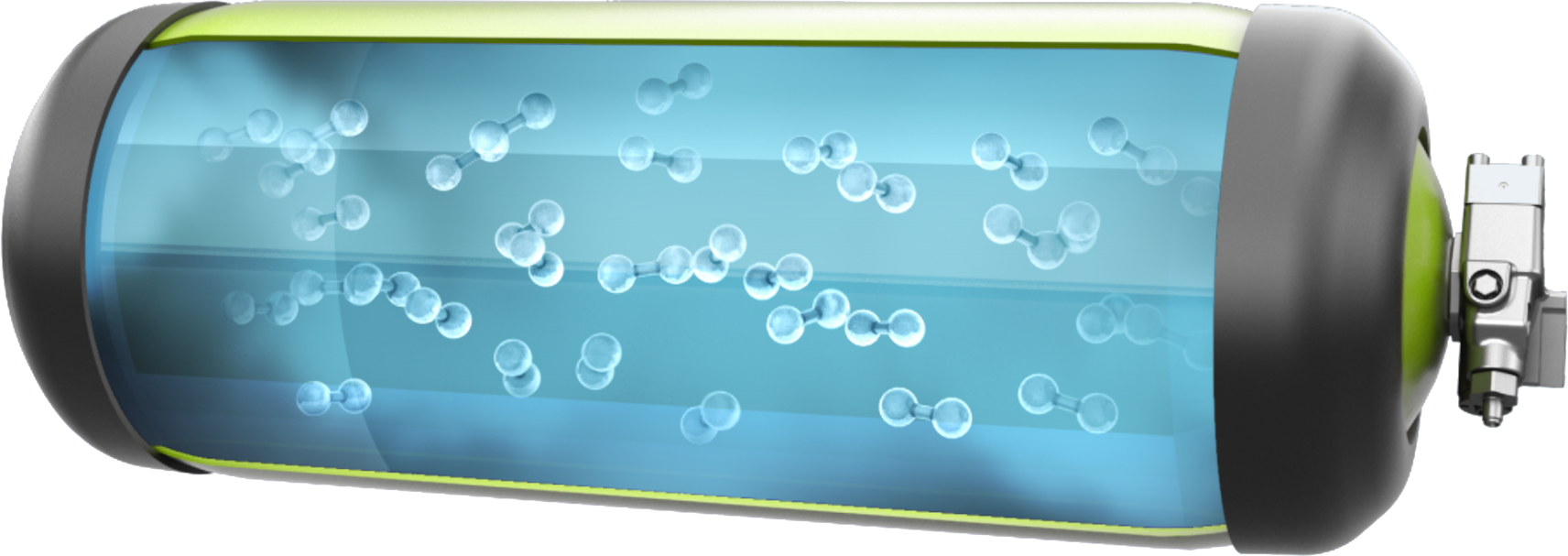

Special composite tanks are used for hydrogen storage with a mass efficiency of 4-7%. Composite cylinders have high operational safety and meet all modern requirements and safety standards.

In case of critical damage, these cylinders are depressurized without any debris. The gas at the exit will quickly evaporate due to the high molecular velocity.

Composite fuel tanks are able to absorb 5 times more impact energy than steel ones. Besides, they can withstand high pressure and are by far the safest solution for storing hydrogen at high pressure.

In case of critical damage, these cylinders are depressurized without any debris. The gas at the exit will quickly evaporate due to the high molecular velocity.

Composite fuel tanks are able to absorb 5 times more impact energy than steel ones. Besides, they can withstand high pressure and are by far the safest solution for storing hydrogen at high pressure.

Power converter is an electronic device operating on the principle of a DC-DC converter and providing a change in the output voltage of the fuel cell to the required voltage of the high-voltage on-board system of the car.

The fuel cell has a very sharp voltage curve, which complicates interaction with third-party consumers. To simplify operation and stabilize the operating voltage, we have developed the power conversion unit. It's stabilizes the operating voltage and increases it to the required 650 volts.

Driving at a higher voltage allows you to use an electric motor more efficiently giving out more power.

The fuel cell has a very sharp voltage curve, which complicates interaction with third-party consumers. To simplify operation and stabilize the operating voltage, we have developed the power conversion unit. It's stabilizes the operating voltage and increases it to the required 650 volts.

Driving at a higher voltage allows you to use an electric motor more efficiently giving out more power.

The control system is another key element of the power plant of a hydrogen car. This unit is responsible for the distribution of energy in the system and connects its necessary elements depending on the load.

The control unit decides when to use the accumulated energy from the buffer battery, when to receive it directly from the fuel cell, and when to use all the sources.

Special software and smart algorithms developed by our programmers make the operation of all the elements highly effective. For better efficiency, the unit is implemented as part of the fuel cell.

The control unit decides when to use the accumulated energy from the buffer battery, when to receive it directly from the fuel cell, and when to use all the sources.

Special software and smart algorithms developed by our programmers make the operation of all the elements highly effective. For better efficiency, the unit is implemented as part of the fuel cell.

A buffer battery, or secondary energy source, begins to work when the car starts. It helps when there is a sharp increase in power, for example during acceleration.

The battery improves the overall efficiency of the car's fuel system and fuel economy as it accumulates energy during regenerative braking.

Unlike batteries in classic electric cars, a hydrogen car battery is small in size and has a longer life time due to low loads.

The battery improves the overall efficiency of the car's fuel system and fuel economy as it accumulates energy during regenerative braking.

Unlike batteries in classic electric cars, a hydrogen car battery is small in size and has a longer life time due to low loads.

We use our own technological developments and know-how to create electric motors. The motors have been thoroughly tested to operate in a wide variety of conditions, which guarantees their reliability and performance.

Thanks to special software, all the car systems work smoothly and at maximum efficiency ensuring the comfort of driving innovative vehicles.

Meanwhile, the components of the power plant based on hydrogen fuel cells allow us to create various types of transport: passenger, freight, railway, etc.

Thanks to special software, all the car systems work smoothly and at maximum efficiency ensuring the comfort of driving innovative vehicles.

Meanwhile, the components of the power plant based on hydrogen fuel cells allow us to create various types of transport: passenger, freight, railway, etc.